Select your region / language

Cooking Systems

Scott supply automated equipment to the cooking appliance industry including oven cavity and cooktop manufacturing systems.

Our oven cavity systems can incorporate deep or shallow drawn rails or pans with wire rack systems in electric, gas or steam variants.

Scott can provide systems for cooker side and back panel manufacturing or fully automated systems for oven and cooktop assembly.

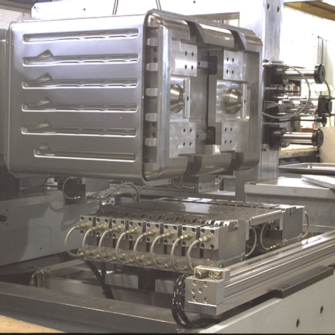

Oven manufacturing systems incorporate embossing, stamping, notching and piercing to form and fold a three or four-sided wrap, bottom, back panel and/or gas burner box.

Products manufactured in cooking production systems are processed from either pre-cut blanks or coiled steel material, based on specification or requirements and can incorporate either spot and or rotary weld systems.

This advanced system features fully automatic tool change along with deep drawing, forming, clinching, trimming, piercing, folding, and robotics technology to produce high quality components at high production rates.

This state of the art manufacturing system was designed, built, and tested at our Appliance Centre of Excellence in Christchurch, New Zealand. Then packed, shipped, and installed at our customers site in North America. This bespoke system fabricates the main oven chassis components and automatically assembles up to 84 brackets with up to 450 rivetless clinch joints per chassis. Scott Appliance Systems provide flexible, repeatable, and robust manufacturing for our customers now, and into the future.