Select your region / language

Five back-end applications

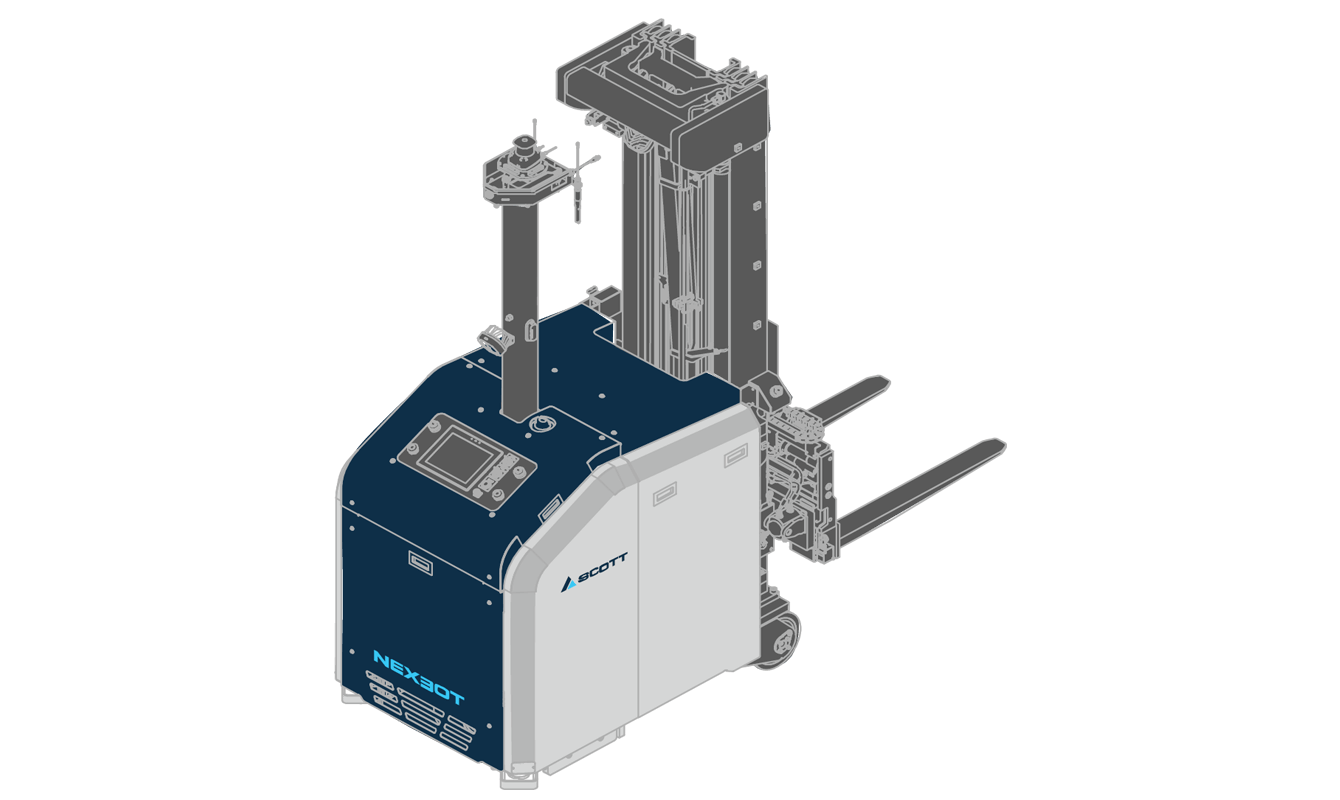

Counterbalanced fork

Counterbalanced fork

The counterbalanced fork is used to automate material handling and transportation tasks, using a counterweight to balance the loads.

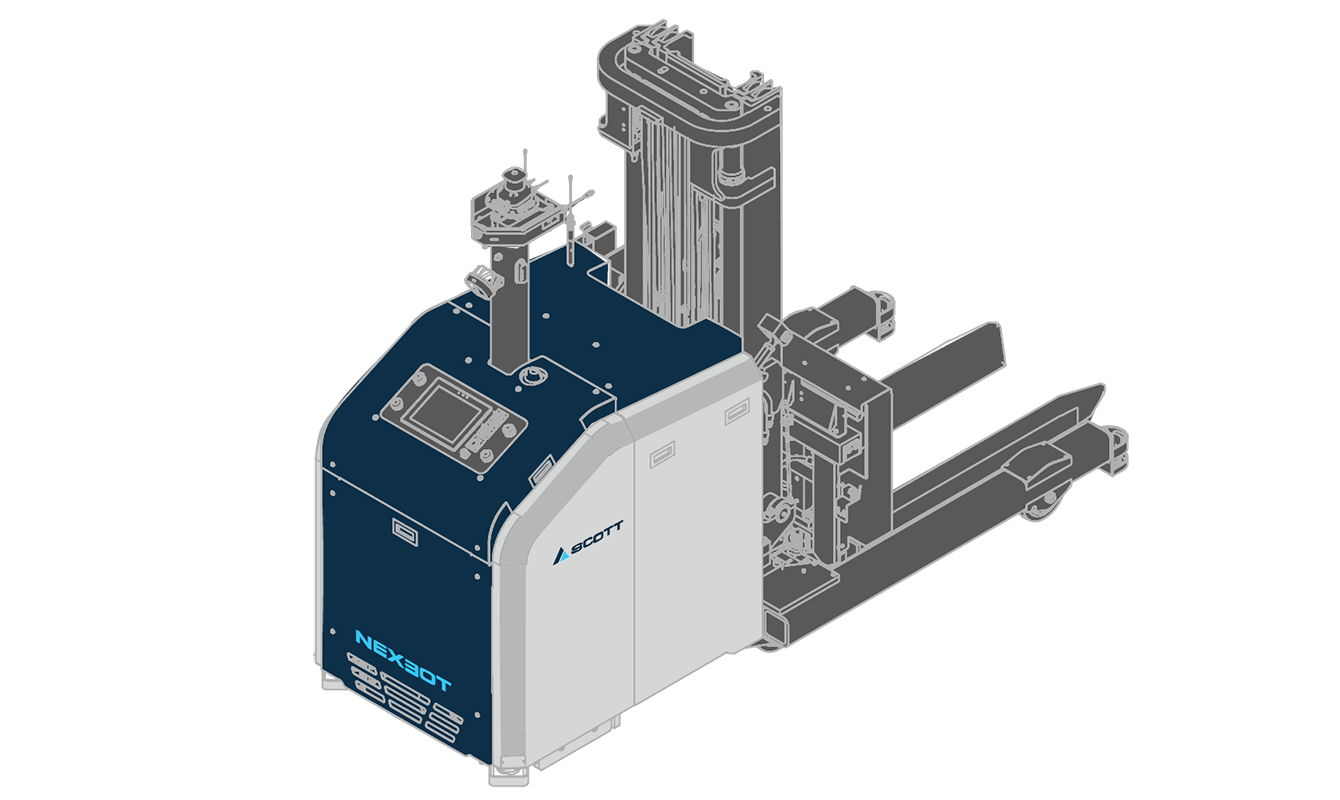

Outrigger / straddle fork

Outrigger / straddle fork

The outrigger, or straddle fork, is used to automate material handling and transportation tasks. The stabilising arm on the back-end of the vehicle is used for vehicle stabilisation when lifting loads.

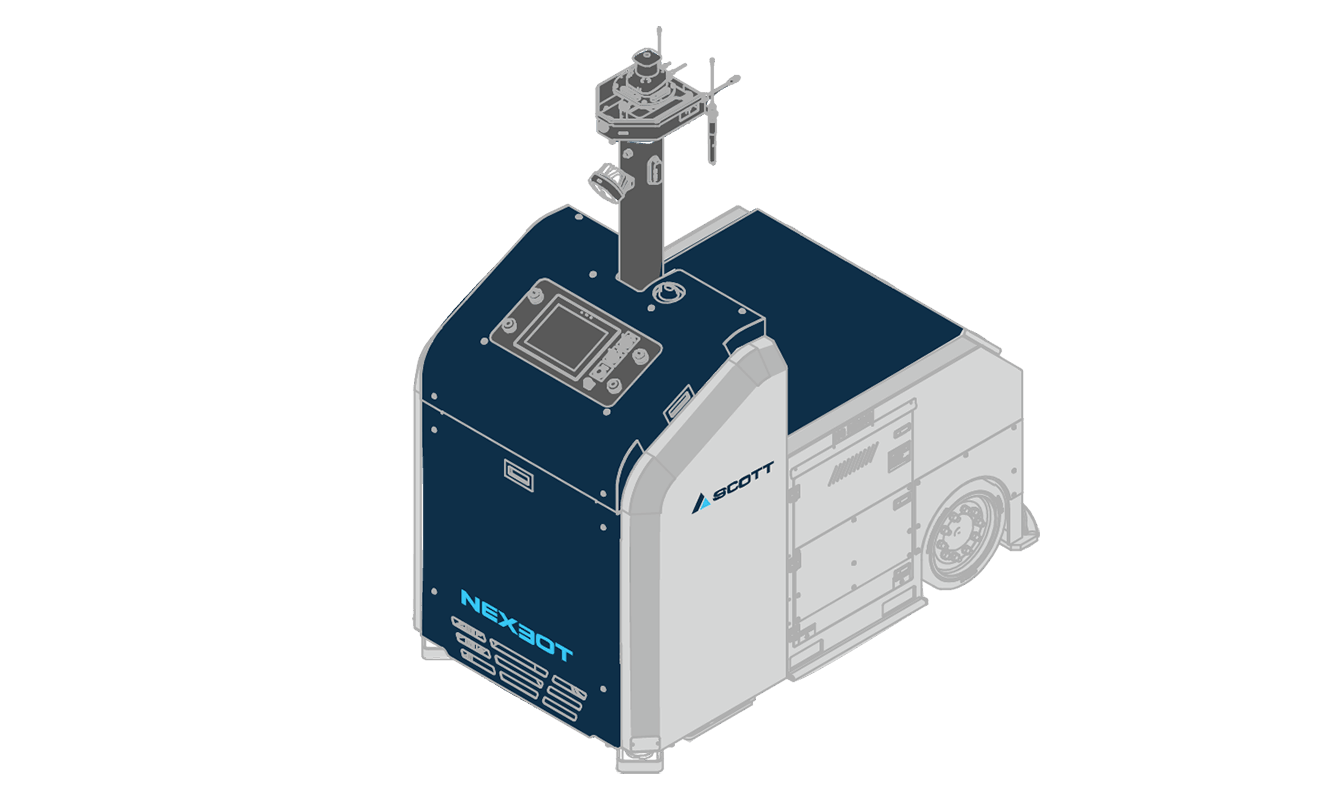

Tugger

Tugger

The tugger is used to efficiently tow or pull cars, trolleys, or trailers via automatic or manual coupling.

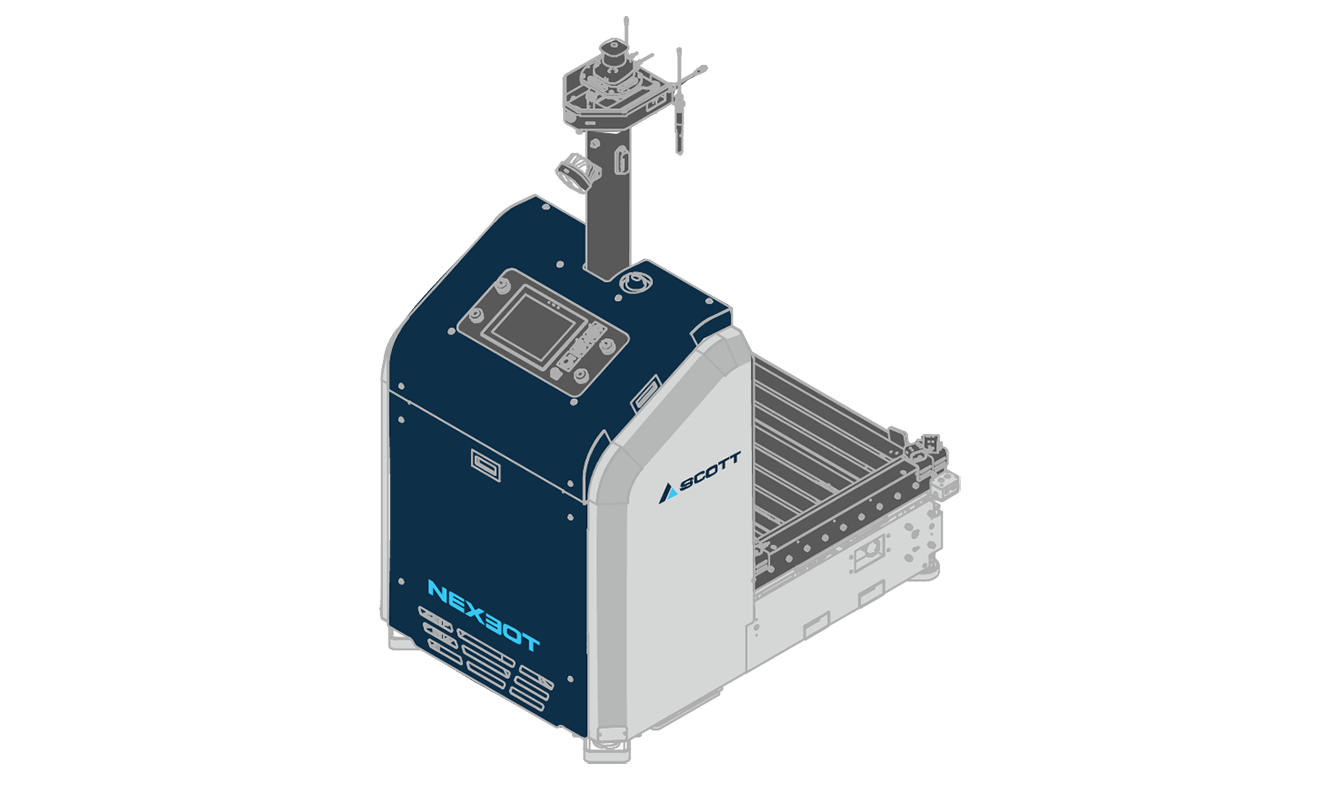

Conveyor deck

Conveyor deck

The conveyor deck is used as a conveyor extension to index pallets, drums, boxes, totes, and skidded items to and from conveyor locations.

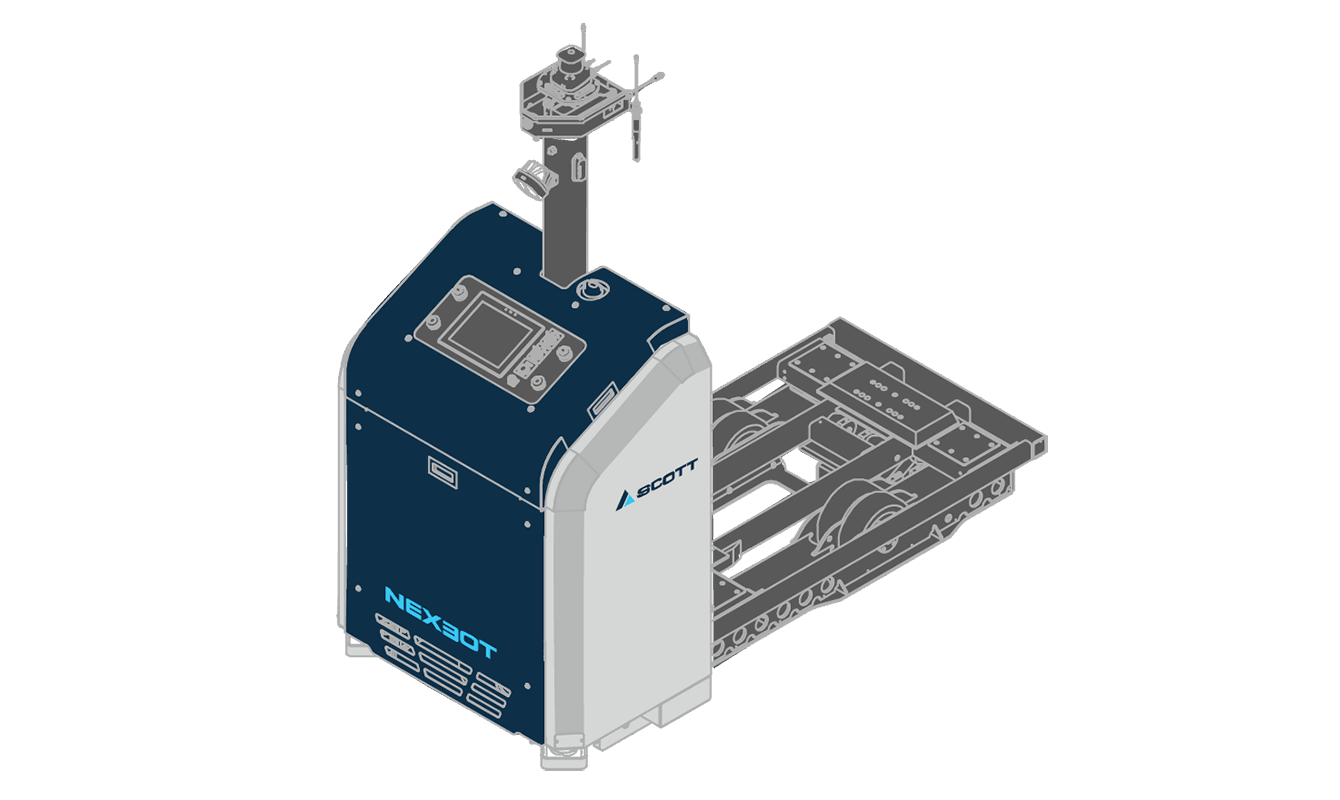

Under-rigger lift deck

Under-rigger lift deck

The under-rigger lift deck is used to automate material handling and transportation tasks, using short-stroke cylinders to lift/lower loads to and from tooling locations.

Don't see the module you need?

Don't see the module you need?

Our modular design allows us to easily build application specific modules.

Four strategic advantages of NexBot

Platform standardisation isn't just good engineering; it's smart business. Here's why your CFO will love NexBot as much as your operations team.

Enjoy low cost implementation with rapid delivery

NexBot's standardised base module keeps costs in check while cutting delivery timelines to just four months. By relying on a single universal platform, production floors gain advanced automation without unnecessary complexity or delays.

Achieve unified fleet software management

All your AGVs run on one single software platform, giving operators a familiar interface and maintenance teams standardised components to work with. This eliminates the hassle of juggling multiple systems and makes fleet management smooth and consistent.

Profit from scalable growth with supplier consistency

NexBot grows with your production demands, whether you deploy one unit or an entire fleet. Its universal platform ensures performance stays consistent and management stays simple, so scaling up doesn't mean headaches.

Benefit from small turning radius for tight spaces

NexBot slips through sharp corners and crowded factory floors while maintaining full payloads. By merging AGV control with AMR-like adaptability, it optimises flow across restricted safety-sensitive, or temperature-controlled areas.

Automation that adapts. Power that lasts

Combining Scott and Transbotics’ expertise in AGV solutions and with a modular, accessible platform, NexBot delivers powerful automation without the complexity — ensuring businesses get more from every move.

Get your NexBot AGV up and running!

Share your specific situation to receive detailed analysis of how NexBot could standardise and optimise your material transport operations.