Select your region / language

Rocklabs AMS Prep Line

The AMS Prep Line is an advanced modular mineral sample prep system that provides automated and efficient crushing, pulverising and dispensing with exceptionally precise results.

Better crushing, better mining.

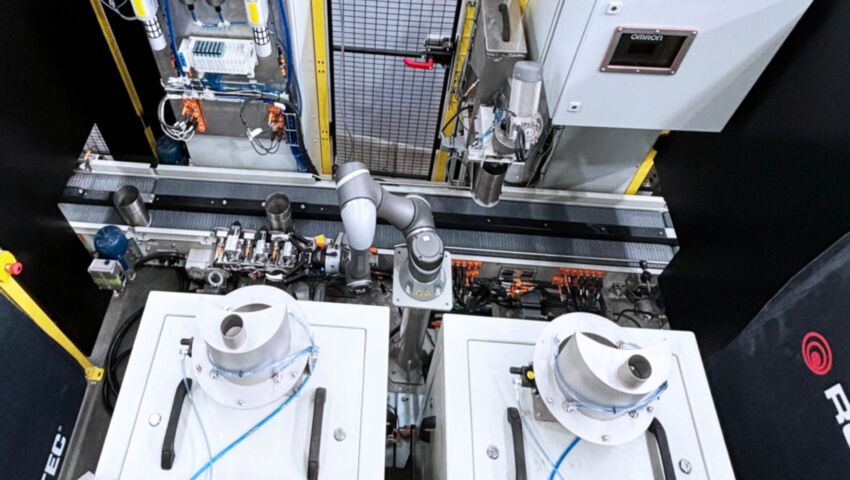

Integrating cutting-edge functionality, the AMS Crusher Module boasts a multi-load sample infeed trolley featuring 21 trays, facilitating the efficient handling of multiple samples.

With the inclusion of a Linear Sample Divider (LSD), sample splitting is executed with precision, ensuring consistent and accurate analysis results.

The AMS crusher module incorporates advanced contamination prevention measures, including air, vibration, and tappers for thorough cleaning, a jaw scraper to detect hang-ups, and RFID sample cup cleaning, ensuring optimal sample integrity and reliability.

With the flexibility of choosing between a Rocklabs Boyd Elite or Mid Boyd Crusher unit it can accommodate diverse sample processing needs. The Rocklabs Boyd crusher pioneered the sample preparation industry as the world’s first double-acting jaw crusher. It has since remained a preferred choice in laboratories worldwide,

lauded for its exceptional performance, easy maintenance, and operational reliability.

AMS Crusher Module Specifications

| Input Size | Up to 100mm |

| Output | 90% Passing / 2mm |

| Throughput | 16 samples per hour @ 5kg 11 samples per hour @ 10kg 6 samples per hour @15kg |

| Capacity | 250g to 15kg |

| Dimension (w)x(h)x(d) | 3400mm x 2400mm x 2400mm |

| Weight | 3,000 kg |

| Voltage | 380V to 480V 50/60Hz |

| Dust Extraction | Equipped with dust extraction connection |

AMS Crusher Module Available as Standalone System

Pulverise guesswork.

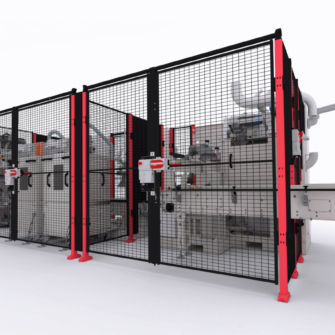

The AMS pulverser module offers versatility, whether as a standalone solution or seamlessly integrated into larger frameworks. Complete with two Rocklabs pulverisers, the system is designed to process a variety of materials, with a very low contamination of samples – because there is no room for error when it comes to your mine’s next move.

To maintain utmost cleanliness and prevent contamination, various methods including sand wash, air, and vacuum cleaning are employed. Serviceability is prioritized, with easy access facilitated through module doors, while interlocks on all doors ensure safety in operation, adhering to AS/NZ 4024 standards.

Additionally, data connectivity via Ethernet enables seamless integration with broader networks for enhanced efficiency and data management. Cycle timer setting includes Processing, Discharge and Cleaning.

AMS Pulveriser Module Specifications

| Input Size | Up to 5mm |

| Output | 95% Passing 75 Micron |

| Throughput | 16 samples per hour @ 5kg |

| Capacity | 250g to 1000g |

| Dimension (w)x(h)x(d) | 2600mm x 2000mm x 2400mm |

| Weight | 2,500kg |

| Voltage | 380V to 480V 50/60Hz |

| Dust Extraction | Equipped with dust extraction connection |

Accurate results, better decisions.

The Rocklabs AMS Dispense Module is the final step of the AMS core, Splitting the sample into small sample ready for sample analysis.

The AMS Dispense module uses Rocklabs highly regarded LSD (Linear Sample Divider) sample divider, designed from the ground up to provide extremely accurate results. Our LSD split out representative portions of the sample to provide best practice, unbiased and proportional sub-sampling with adjustable split ratio and either single or duplicate outputs. Rocklabs sample dividers are able to take accurate and representative splits.

The Sample dispensing head facilitates the filling of sample vials. Complete with Barcode printer enables the printing of sample data onto sample packets.

AMS Dispense Module Specifications

| Input Size | Up to 5mm |

| Output | 30g to 100g Vial and Chyrsos Jars |

| Throughput | 16 samples per hour @ 5kg |

| Capacity | 500g to 1000g |

| Dimension (w)x(h)x(d) | 3400mm x 2000mm x 2400mm |

| Weight | 2,000kg |

| Voltage | 380V to 480V 50/60Hz |

| Dust Extraction | Equipped with dust and waste connections |

Are you ready to take your mineral mining sample preparation to the next level?

Don’t miss out on the opportunity to enhance your lab’s capabilities with the latest in automation technology register for AMS Prep line Introduction Session.