Select your region / language

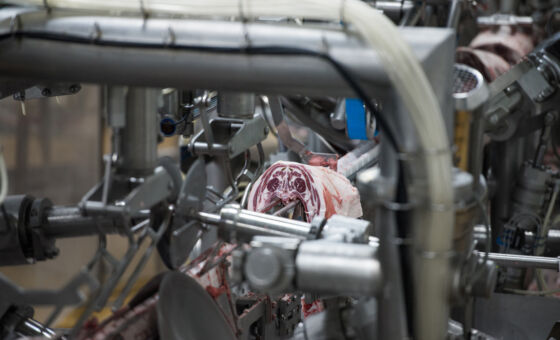

Spotlight on Meat Processing Automation

High meat prices and significant labour constraints have put a spotlight on automation as a means to gain substantial uplift in earnings and future proof operations for meat processing clients globally as we enter a post pandemic world. Scott have achieved significant milestones in recent months with lamb, beef and poultry automation as well as the widely recognised BladeStop product. A high level of demand for automation is being experienced globally and Scott are proud to have solutions that are matured and embedded as the workhorse of industry. We are pleased to provide this update.

LEAP Improvements & Lamb Processing

For small stock processors, Scott have made further improvements to the LEAP (automated carcass processing system) that are incorporated into two new systems being built for commissioning early and mid-2022 that will further increase benefits attained by processors. Additionally, Scott have released, and installed, the next generation of “industry standard” VIP Shoulder puller (MILMEQ/Scott) to further improve reliability, suitability to newer/faster chains as well as improve safety.

Poultry

For our poultry clients Scott have successfully commissioned the first trussing systems into America with pleasing results. We have also further expanded the solution to include additional tail cutting capability. Scott are now working on continuing to improve and support our clients in the region as we look to the opportunity to build further systems.

BladeStop & Materials Handling

We have reached new milestones for the BladeStop™ safe stop bandsaws with more than 1,500 saws in operation globally. Our Materials Handling sector (including carton conveying, storage and retrieval, high speed palletising, pallet conveying and AGV’s as well as specialised carton and pallet preparation equipment) continues to see a strong level of interest with a significant turnkey system being built for commissioning into New Zealand in 2022.