Select your region / language

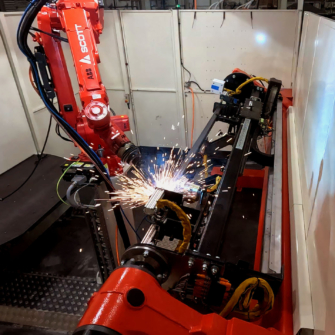

The Advantages of Robotic Welding

With the welding trade facing significant skill shortages and technology continuing to revolutionise every facet of the industrial and manufacturing industries, Robotic Welding can be the solution to many small and large businesses within the welding trades.

Robotic Welding offers many advantages that outweigh the immediate upfront cost and can assist the manufacturing industry in overcoming the challenge of skill shortages while introducing new efficiencies to organisations.

Safety

Having a Robotic Welding System can greatly reduce the risk to workers. It reduces exposure to UV light and to carcinogens found in welding materials. It also removes the risk of burns and electrocution, which are common injuries within the welding industry.

Reduced Waste

Mistakes can happen, and over time can be the cause of wasted materials and more time spent on reworks. Robotic Welding, once programmed with set specifications, can operate with precise execution, eliminating reworks, and thus wasted material. You have control over how much material goes into each weld, also eliminating cost variations.

Flexibility

With many installations and accessories available, a Robotic Welding System can be adapted to your need. From a fully automated production line with multiple welders working together, to a cobot system, where man and machine operate together.

Robotic Welding Solution Achieves 64% Reduction in Cycle Time

Investing in an automated system to overhaul manual technique resulted in a vast improvement in production time for heavy-duty trailers specialist Drake Trailers, resulting in a massive 64% reduction in cycle time.