Select your region / language

Multi-line palletising versus dedicated line palletising in conventional automation solutions

This report offers a comparison of a multi-line palletsing and dedicated line palletising system and the pros and cons, while presenting Scott Automation’s innovative solutions for each.

Introduction

Palletising plays a key role in high-volume manufacturing, especially for facilities running multiple production lines simultaneously. The decision between multi-line palletising and dedicated line palletising is a significant choice that must be made. This report offers a comparison of both systems, the pros and cons, while presenting Scott Automation’s innovative solutions for each.

Multi-line palletising system

Multi-line palletising is the use of a single palletiser to handle multiple production lines. This approach is beneficial for facilities that must palletise a variety of products and require flexible handling capabilities.

Advantages:

- Space Savings: Multi-line systems use floor space more effectively by consolidating palletising operations and having accumulation above the palletisers.

- Lower cost of ownership: Reducing the number of palletisers cuts down on equipment costs, utility requirements, and maintenance.

- Increased productivity: Capable of handling multiple SKUs, these systems can adapt to product changes quickly, reducing changeover time.

Constraints:

- Complexity in programming: Requires a high-level of expertise to calculate accumulation and program SKU release timing.

- Potential for bottlenecks: If accumulation system is not designed properly, peak production from multiple lines could overwhelm the palletiser, leading to product backing up.

Dedicated line palletising systems

Dedicated line palletising involves using a separate palletiser for each production line. This system is traditionally favored in environments with high volume and limited variation in product type.

Advantages:

- Simplicity: No need for accumulation calculations to ensure a proper buffer. Operators do not have to worry about maintaining accumulation conveyors and palletisers will likely be common.

- Predictable: One production line per palletiser means the palletiser is not making adjustments between each load.

- Optimized performance: Each system can be optimized for a specific product line. When an additional line is added, it simply calls from another palletiser without worrying about how it might affect the other lines.

Constraints:

- Higher cost of ownership: Requires investment in multiple palletisers and while they may share common components, you could incur higher operational costs.

- Space requirements: Occupies more floor space, which could be a limiting factor in space-constrained facilities.

Scott's palletising solutions

Scott offers conventional and robotic palletising solutions designed to meet the ever-changing needs of manufacturing. By focusing on innovative design and robust construction, Scott Automation's palletisers enhance operational efficiency, reliability, and scalability.

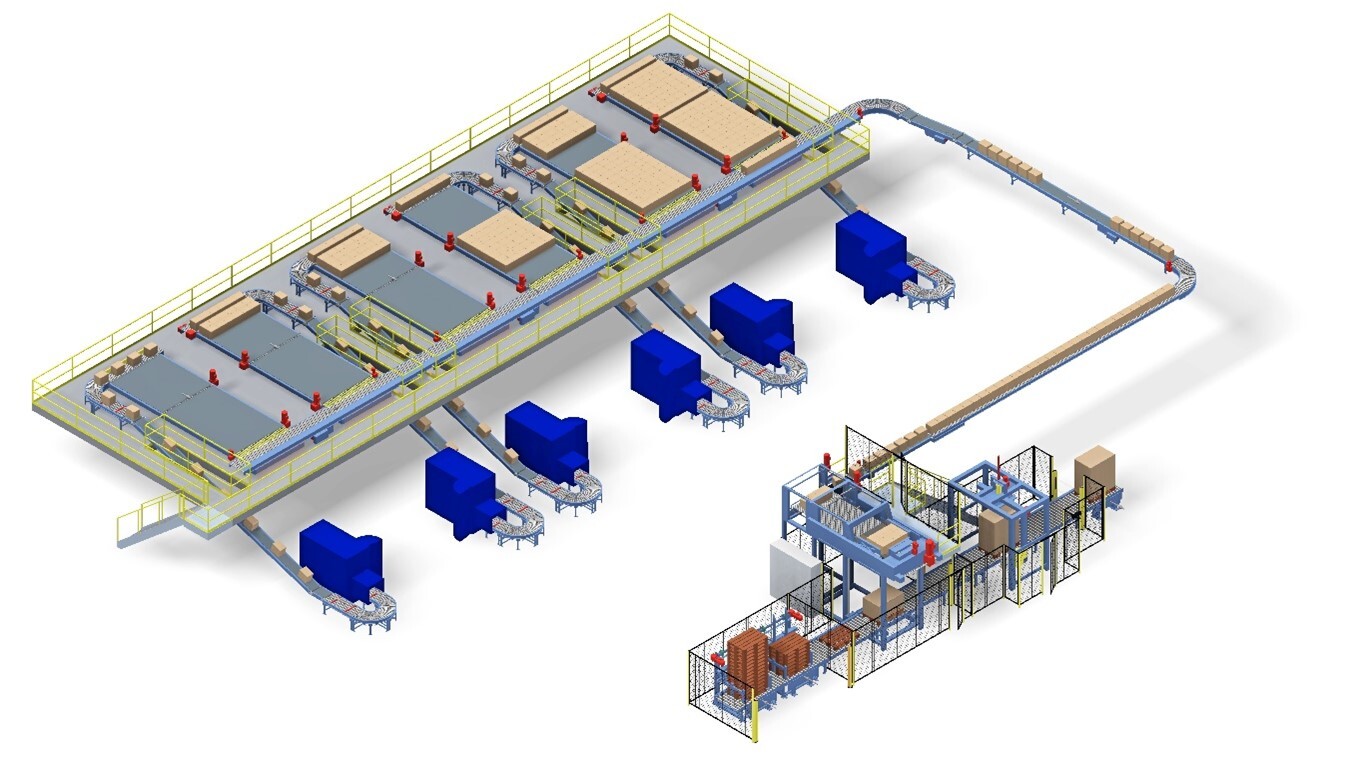

Multi-line palletising with Scott:

Scott's multi-line palletisers are engineered for flexibility and efficiency. Scott’s unique accumulation tables minimize the amount of conveyor required to buffer products and can release full loads to the palletiser quickly. The system may be equipped with our Maestro+ software package that adds 4.0 data collection to simplify controls and seamlessly integrate with an existing warehouse management system.

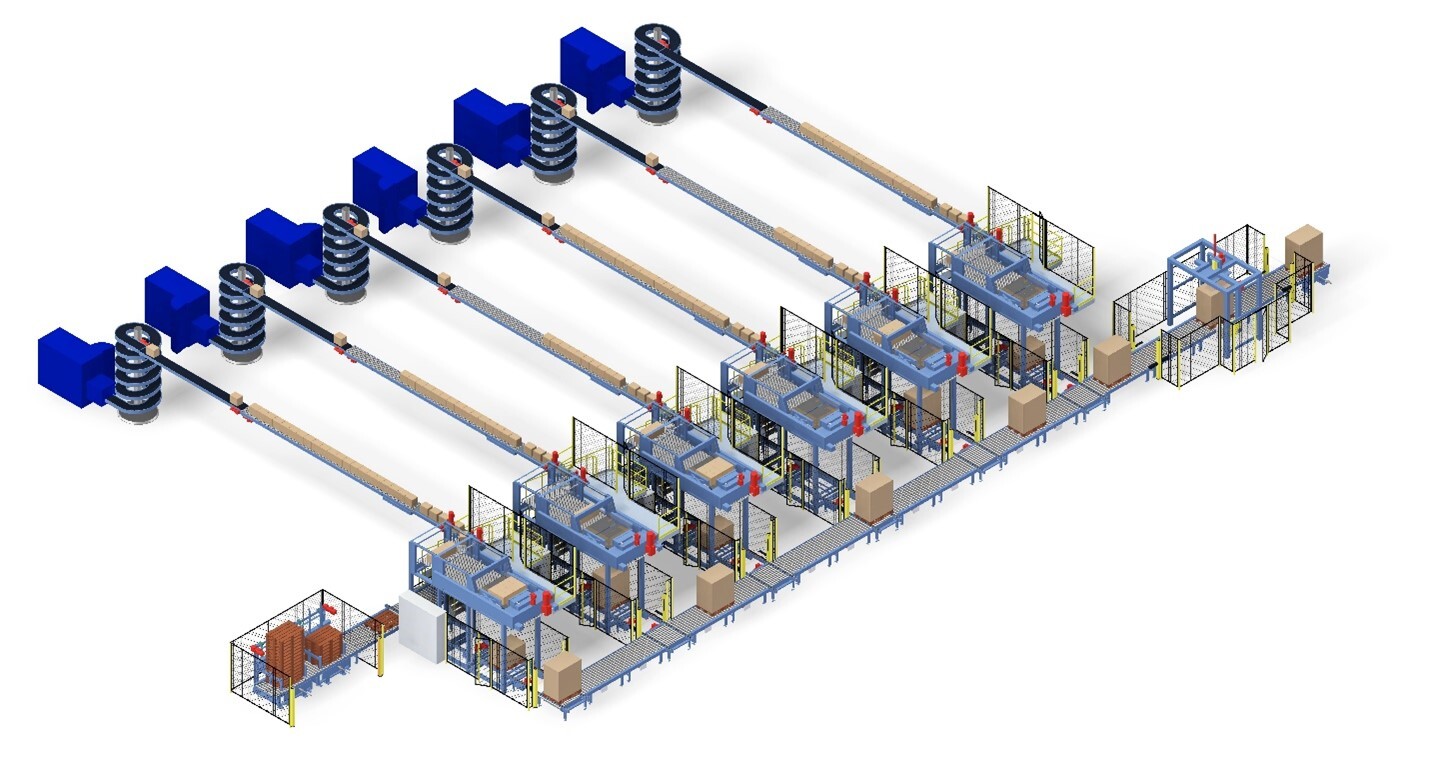

Dedicated line palletising with Scott:

For operations prioritizing throughput and redundancy, Scott’s dedicated line palletisers offer a compelling solution. These systems are designed to maximize operational uptime and are customized to meet specific production demands, ensuring consistent performance under continuous use. While the palletisers are often the same as used in multi-line, using them as dedicated palletisers allows you to run them at slower speeds, thus decreasing wear.

Conclusion

Choosing the right palletising solution for your operation depends on several factors. Scott is happy to provide expert guidance so that you may achieve optimal efficiency and productivity. With Scott's robust and scalable systems, you may confidently address your automation needs, ensuring a competitive advantage for the future.