Select your region / language

SCOTT delivered a new high speed palletiser for a leading UK dairy

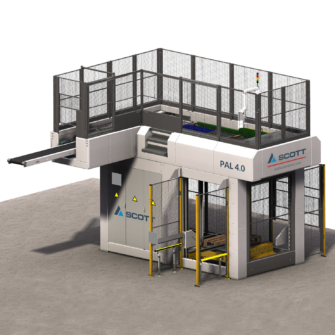

Palletising specialists SCOTT Automation recently supplied and installed a high speed model from their successful new range of PAL 4.0 Palletisers for a leading producer in the UK dairy industry.

Capable of handling both plastic and cardboard trays at line speeds approaching 90 trays per minute, the twin infeed palletiser is designed to cope with the progressive change from plastic to cardboard trays now being implemented throughout the dairy and associated industries.

With the latest in HMI and control systems integrated into the palletiser for ease of operation and user friendliness, data is linked to the factory management system via SCOTT´s Maestro industrial software package – a web-based, efficient, cost effective and fully modular system.

Although achieving the consistently high throughput speeds necessary for this contract, design features of the PAL 4.0 model ensure careful tray handling at all stages of the palletising process and maintain product integrity throughout. It also ensures perfectly built pallets are forwarded on to the client´s eventual customers.

With many years of supplying palletising systems to Dairy Industry clients across Europe and the UK under the SCOTT or previously ALVEY banners, the Company is finding that growth in the chilled and frozen dairy products market is creating more opportunities for SCOTT to provide cost and space effective solutions to the need for efficient palletising and pallet handling systems. Matching innovative and efficient designs to help streamline and optimise customers´ production lines is the SCOTT hallmark.

If you have a project in the Dairy or Chilled/Frozen Food supply chain, can we offer our assistance in developing your end of line palletising solution?

Learn More About PAL 4.0

PAL 4.0 is the latest addition to our range of palletisers. It was developed in conjunction with our key partners and is equipped with the latest technology and components.