Select your region / language

Conventional palletising vs. robotic palletising

This white paper provides an in-depth comparison of the two most common palletising solutions: conventional (or layer palletising) systems and robotic palletising systems. It examines the benefits of each method in the context of modern manufacturing requirements. Additionally, this paper highlights the innovative solutions provided by Scott, which integrate the advantages of both systems, offering a hybrid approach to palletising.

Introduction

Palletising, the process of stacking products on a pallet for transport and storage, is a critical aspect of manufacturing and distribution. The efficiency, reliability, and flexibility of the palletising system can significantly impact operational productivity. Traditionally, this process has been categorized into three types: manual, conventional (layer), and robotic palletising. Each method has distinct characteristics and benefits suited to different operational needs. For brevity, this paper will omit manual palletising.

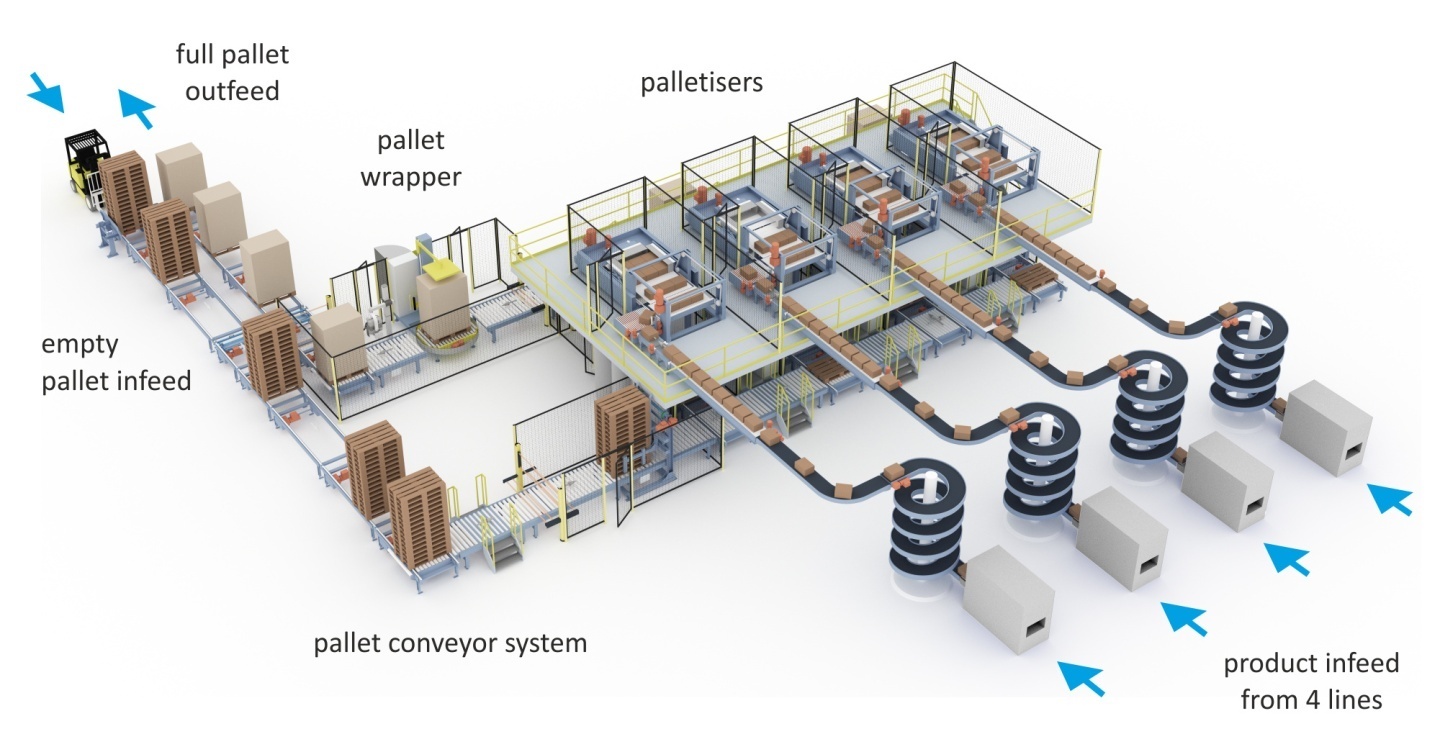

Conventional palletising

Conventional palletising systems, also known as layer palletisers, stack products in a predetermined sequence, creating stable and uniform layers on a pallet. Product is brought into the machine on an infeed conveyor, cases are turned to form specific patterns, and then the row is raked onto an apron. Once a full layer is formed, the apron moves away to deposit the layer on the pallet.

Benefits:

- Higher production rates: Conventional palletisers are renowned for their speed and efficiency. They are capable of handling high-volume product flows (upwards of 150 cases per minute), making them ideal for high-capacity operations.

- Handling multiple case sizes and types: Because the bottom is conveyed across rollers or a mat top, the palletiser may only require minimal adjustments if any at all. These systems can easily adapt to different case sizes and types, allowing for a versatile palletising process suited for varied product lines. Most new systems have added automatic adjustments to eliminate the need for change-over time.

- Simple operation and maintenance: The mechanical simplicity of conventional palletisers makes them relatively easy to operate and maintain, requiring less specialized training for personnel. Conventional palletisers typically incorporate industry-standard PLCs and HMIs to make things easier on the operator.

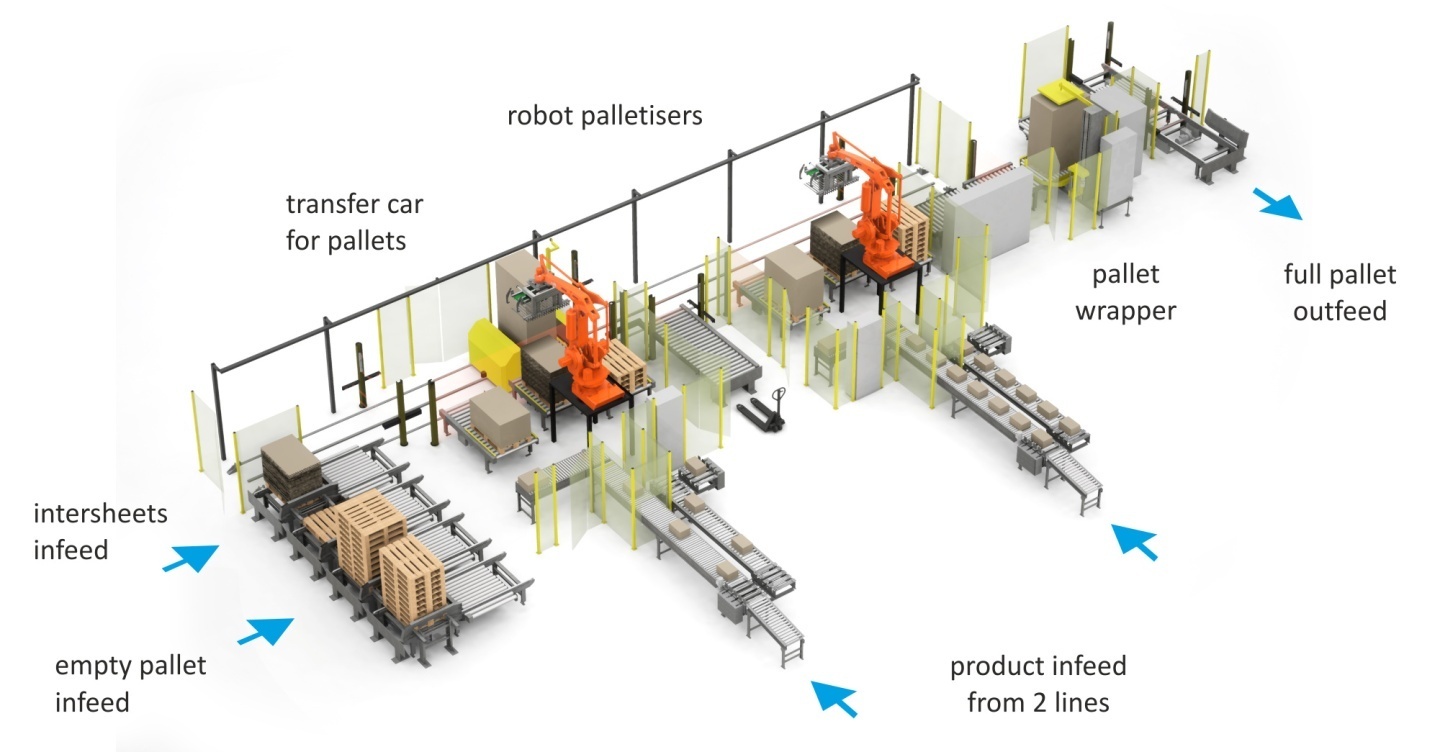

Robotic palletising

Robotic palletising involves the use of robotic arms, equipped with various end-of-arm tools, to pick and place products on a pallet. End-of-arm tools may be custom designed specifically for a customer’s product. This method offers greater precision as well as label orientation during placement.

Benefits:

- Simultaneous multi-line palletising: Robotic palletisers can build different product loads simultaneously, making them ideal for operations that require palletising a variety of items concurrently.

- Label orientation control: These systems can orient products based on label positioning, ensuring that labels are visible and correctly aligned, which is crucial for retail and customer-facing products. Vision systems may be added to further improve accuracy.

- Adjustable infeed elevations: Robotic palletisers offer flexibility in infeed elevation, accommodating different product lines and operational layouts without extensive mechanical restructuring. Pick-up points do not need to all be at the same location so long as they are within the arms operating reach.

Comparison and considerations

When choosing between conventional and robotic palletising, factors such as product type, production volume, space, and workforce must be considered. Conventional palletisers are best suited for high-capacity, uniform product lines, while robotic palletisers excel in environments requiring flexibility and precision handling.

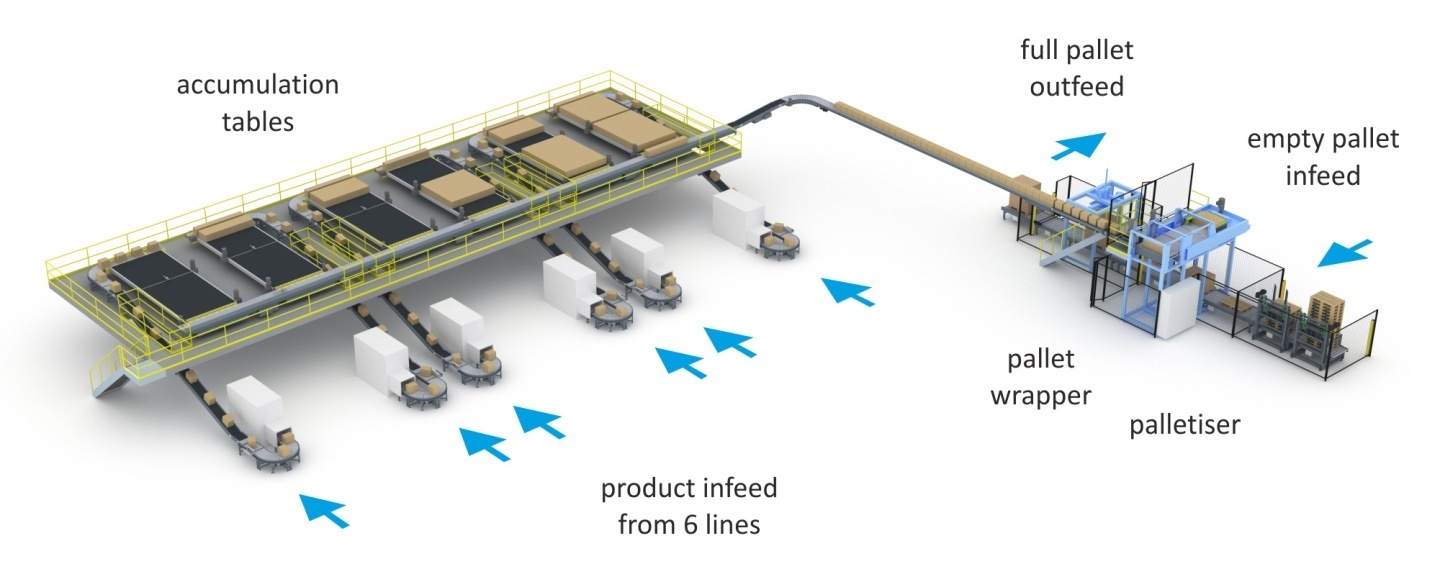

Scott's innovative solution: A hybrid approach

Scott presents an innovative solution that bridges the gap between conventional and robotic palletising. Scott's advanced accumulation tables allow customers to enjoy the benefits of both systems by storing at least a full pallet worth of product before sending it to the palletiser. Depending on the customer’s overall production rate, up to ten tables could feed a single palletiser.

Key Features:

- High-capacity palletising: Like conventional systems, Scott's solution supports high-capacity palletising, ensuring productivity in high-volume scenarios. Multiple palletising options provide capacities from 20 cases per minute up to 150 cases per minute.

- Multi-line capacity: Incorporating the storage capacity in the accumulation tables, it can handle multiple product lines simultaneously, a feature typically associated with robotic palletisers. Whereas a robotic palletiser may be at the limits with a total production rate of 20-30 cases per minute, accumulation tables allow four or five lines EACH running 20-30 cases per minute to feed a single palletiser.

- Integrated system design: This solution provides an integrated approach, combining the efficiency of conventional palletising with the adaptability of a multiline system.

Conclusion

The choice between conventional and robotic palletising depends on specific operational needs. However, Scott's innovative accumulation tables offer a hybrid solution, merging the high-capacity capabilities of conventional systems with flexibility and precision. This integrated approach represents a significant advancement in palletising technology, offering businesses a versatile and efficient solution to meet diverse and evolving palletising demands.